The world of the

REMONDIS Lippe Plant

REMONDIS makes the very most of residual materials even if they can’t be recycled. There’s a whole load of energy hidden in waste just waiting to be used. For example, incinerating

non-recyclable waste in the environmentally friendly fluidised-bed power station.

Substituting fossil fuels means a better carbon footprint – one of the great advantages of the fluidised-bed furnace

As is the case with so many of the buildings at the Lippe Plant, the fluidised-bed furnace has a very special history. Back in the middle of the last century, when the site was still being used to produce aluminium, the power station was a travelling-grate boiler fired purely with coal. Today’s fluidised-bed power station was then built to replace this facility at the beginning of the 80s. The combustion process used here was developed together with the company, Lurgi. For over 35 years now, the fluidised-bed furnace has been supplying the site with electricity, process steam and compressed air. And, of course, investments continue to be made in the fluidised-bed furnace to further increase the efficiency of the combustion process and, consequently, make it even more environmentally friendly. In 2015, REMONDIS spent 6.5 million euros on installing a new steam boiler. This has led to the amount of process steam and electricity being produced increasing by over 20 percent.

The precision and quality of the work to install this extremely heavy boiler were truly impressive: the following video documented the project

As a general rule, the power station only generates energy using material which can no longer be reused. This means that it really does only incinerate materials that cannot be recycled or that contain contaminants that are unable to be removed. As it is also an environmentally friendly way to treat hazardous waste, the power station’s input material always undergoes stringent safety checks and is inspected by Umwelt Control Labor as soon as it arrives at the site.

Learn more about fluidised-bed combustion at lippewerk-kraftwerk.de (German)

The waste hierarchy forms the basis of the German Circular Economy Law [KrWG]. It stipulates in which order waste should be handled. Top priority is given here to reducing the amount of waste actually generated. This is then followed by reuse, recycling and recovery, (i.e. recovering energy from waste). The fifth and last option is sending waste to landfill. Learn more about the KrWG

All in all, the fluidised-bed furnace has twelve separate facilities able to accept waste, which means it can store a whole range of different types of waste before they are transferred for incineration. These facilities include silos, tanks and underground bunkers. The furnace is supplied with a range of materials including shredded waste from two facilities located at the Lippe Plant: the recyclables processing facility and the facility dedicated to sterilising healthcare waste. Having said that, the majority of the material comes from external companies – such as sewage sludge and filter earths as well as liquid waste from the chemical and pharmaceutical industries.

Material being delivered by lorry

Efficient and low on emissions: even though an ever increasing amount of material is being incinerated by the fluidised-bed furnace, its emissions have remain unchanged for many years.

The most distinctive feature of the circulating fluidised-bed power station is the way the ash is handled. In fact, the name – circulating fluidised bed – says it all as air and circulation play a major role here. The red-hot bed of sand and ash is lifted and kept circulating by a cyclone, creating the best possible combustion conditions and ensuring the materials are completely burned. State-of-the-art technology is in use here to make sure that the best combustion temperatures are achieved and that the power station works efficiently. It goes without saying that top priority is – as always – given to protecting the environment. By the way, this not only involves the whole subject of emissions but also the use of process water. This water is produced and supplied at the Lippe Plant, helping to reduce consumption of drinking water.

Good combustion – also of ash-rich material that is not easily combustible

Relatively low combustion temperatures mean there is no thermal nitric oxide formation

Adding powdered limestone creates a more direct and simpler flue gas desulphurisation process

An effective combustion process thanks to the efficient transfer of heat

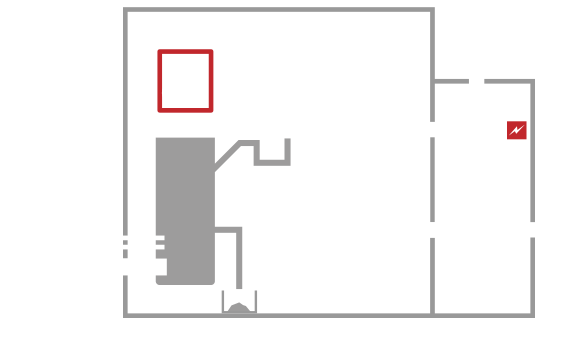

We have drawn up the following chart to show how the power station works. The focus here lies on the circulating fluidised-bed combustion (CFBC) process and the production of steam and electricity resulting from this. We deliberately chose to exclude areas such as feedstock handling and the production of compressed air as well as the specifics of the flue gas desulphurisation process to prevent the whole thing from becoming too complicated and overly technical.

Learn more about the synergies at the Lippe Plant

Thanks to the fluidised-bed furnace, the Lippe Plant has a good supply of energy. Certainly an important point as Germany gradually switches from fossil fuels to renewables – in a time, therefore, where there are still some concerns about whether there will be a reliable supply of electricity in the future. The fluidised-bed furnace not only supplies the facilities at the site with electricity but also with process steam and compressed air – proving to be an excellent example of environmentally friendly cogeneration. Any surplus electricity is fed into the national grid. The fluidised-bed furnace is, therefore, able to extend its positive impact beyond the Lippe Plant itself. Indeed, it is a great example of how the energy switch can be implemented as generating electricity with waste rather than fossil fuels is not only future-proof, it also helps to conserve natural resources and curb climate change. It goes without saying that all emission limit values are strictly adhered to – also thanks to its comprehensive, state-of-the-art flue gas cleaning system – and permanently monitored online by the district government.

REMONDIS Production is responsible for running the fluidised-bed furnace. This company operates a variety of business divisions and has several different facilities at the Lippe Plant. Find out more about REMONDIS Production

Diese Seite verwendet aktuelle Techniken, die in dem von Ihnen verwendeten Browser unter Umständen nicht korrekt

angezeigt werden können.

Bitte aktualisieren Sie Ihren Internet-Explorer oder weichen auf einen anderen Browser wie Chrome oder

Firefox aus.

Schließen