The world of the

REMONDIS Lippe Plant

High risk material is an unavoidable by-product of today’s agricultural and food industries. It goes without saying that we give our full attention to this by-product at the Lippe Plant as well. This includes recycling all the material either to produce energy or – ideally – for reuse. For example to make leather.

A description of the facility

How the disposal process works.

Responsibility

Adding value to the disposal process

From a high risk material to an environmentally friendly fuel.

SecAnim is the company responsible for operating the facility that disposes of high risk animal by-products

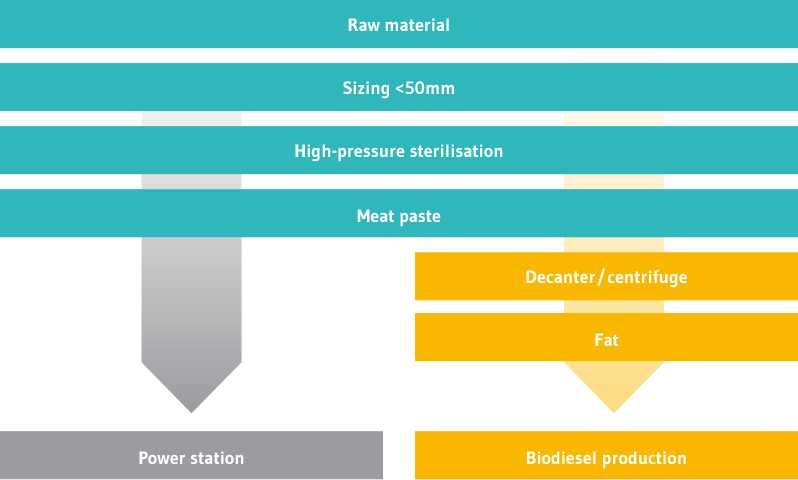

We all live in a society that uses and consumes animal products on a grand scale. This is something that we may, can or perhaps should be critical of. Whatever the case, this is the situation we face today and solutions need to be found for disposing of carcasses. This not only includes abattoir waste that is not fit for human or animal consumption but also fallen farm stock. These carcasses must be collected and processed in accordance with stringent regulations to prevent the spread of disease. The latter is particularly important. At the end of the day, handling high risk animal by-products involves high levels of responsibility towards both humans and animals. We have taken on this task at the Lippe Plant. With a facility that not only provides a reliable and safe way to dispose of carcasses but also recycles the materials in line with strictly defined and monitored framework conditions. These include recovering material for making leather as well as producing meat paste as a fuel and using animal fat to produce biodiesel.

The fully automated sterilising units are operated at 133°C and 3 bar

One big advantage of the facility disposing of high risk animal by-products at the Lippe Plant is its fully closed system. At no stage does the material come into contact with the outside world – from its collection at farms and meat processors, to its transfer into the facility, all the way through to its disposal. Even the transport routes within the Lippe Plant are sealed off. The meat paste that is used as a fuel, for example, is transferred via air-tight pipes from the disposal plant straight to the fluidised-bed furnace, where it is thermally treated. We fulfil all legal regulations regarding the handling of high risk animal by-products. The meat paste produced as part of the disposal process is sterilised in our facility for 20 minutes to destroy any possible bacteria, viruses or pathogens. Priority is also given to hygiene outside the facility. The vehicles used to collect the material are disinfected after every delivery.

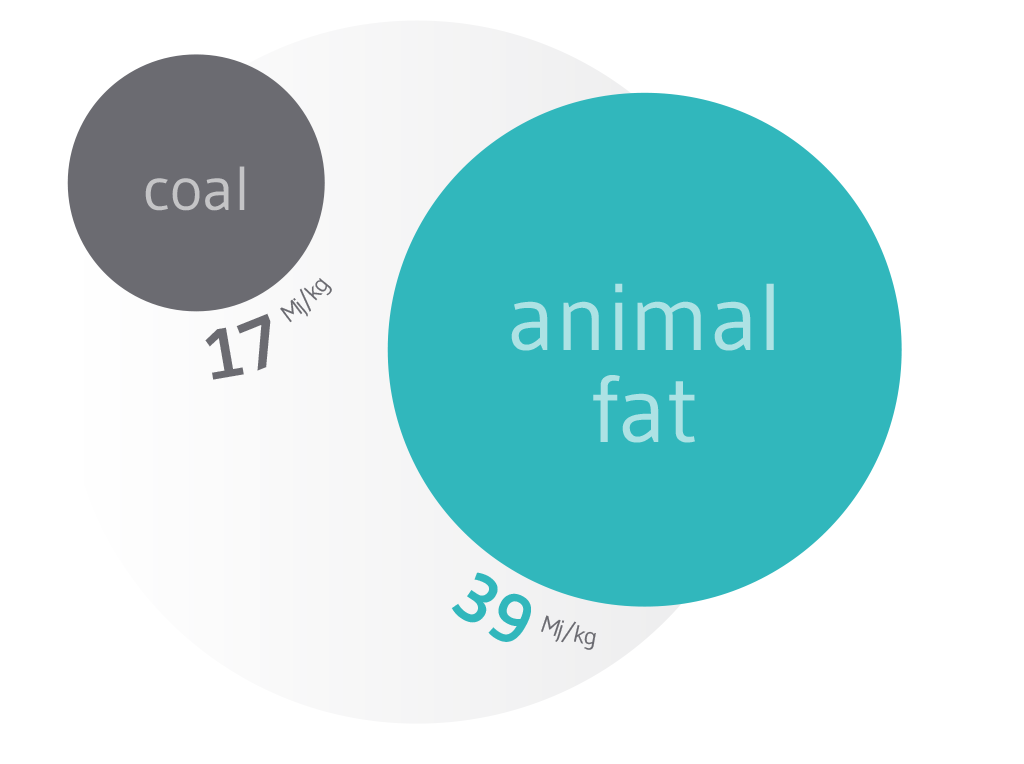

A great advantage of processing high risk animal by-products is that this obligatory task can be turned into something useful. This process generates end products such as meat paste and animal fat. Both products have something in common: they have a high calorific content and so are an ideal source of energy. Using them as an RDF or to produce biodiesel conserves considerable amounts of primary raw materials, such as coal and oil. Which also helps curb climate change. Biodiesel made from animal fat, for example, produces 90% fewer greenhouse gas emissions than fossil fuel. The recycling of the animal hides also plays a sustainable – if small – role in this process. We are able to supply the leather industry with around 15 tonnes of hides every year. Proof, therefore, that the most really is made of all the materials.

A genuine alternative source of energy

The calorific value (Mj/kg) of animal fat is more than twice that of the fossil fuel, coal.

SecAnim – experts for high risk animal by-products – excels for a number of reasons, one of these being its fast logistics. Its special trucks are able to collect high risk animal by-products at short notice

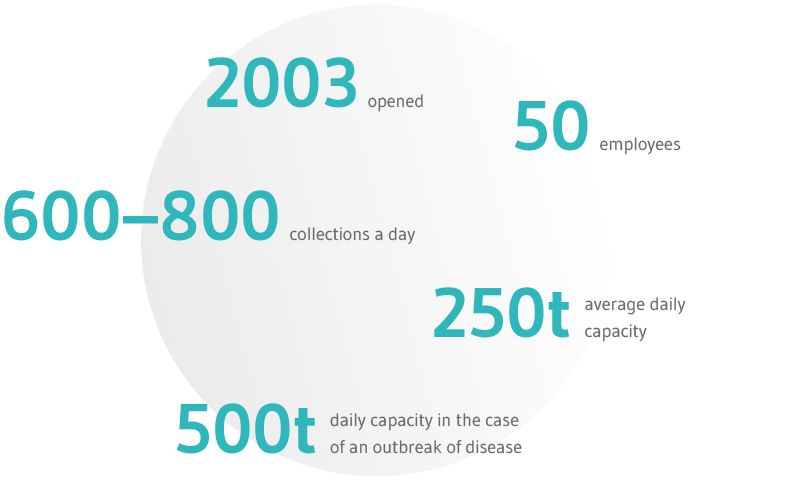

At no point can the material being treated be seen as all the different facility units are completely covered. Having said that, though, it’s well worth taking a look at the company’s figures. Every year, a total of 77,000 tonnes of incoming material is processed (as of 2016). This recycling process generates 4,000 tonnes of animal fat as well as 73,000 tonnes of meat paste. The Lippe Plant has a few more impressive figures for this facility. Would you like to see some?

Stainless steel and highly polished surfaces wherever you look. Cleanliness is one of the trademarks of this facility

What happens during the treatment of the high risk animal by-products is certainly not appetising. It is, however, necessary. This is the only way to ensure that substances that may be harmful to humans and animals are safely disposed of and that sustainable fuels are produced. The special feature of the facility at the Lippe Plant is that it doesn’t need the standard drying process used at similar plants. This is possible because the fuel is incinerated and turned into electricity at the Lippe Plant itself which means it doesn’t have to be processed for transport.

The processing & disposal of high risk animal by-products at the Lippe Plant

Diese Seite verwendet aktuelle Techniken, die in dem von Ihnen verwendeten Browser unter Umständen nicht korrekt

angezeigt werden können.

Bitte aktualisieren Sie Ihren Internet-Explorer oder weichen auf einen anderen Browser wie Chrome oder

Firefox aus.

Schließen