The world of the

REMONDIS Lippe Plant

What do smart walls and floors have in common with sulphurous flue gases? A great deal actually. The flue gas desulphurisation systems at power stations generate the by-product, FGD gypsum. A raw material that is of the same high quality as natural gypsum and can be used to make a wide range of products such as top quality wall plaster and floor screed.

Areas of use

Production process

A unique process is used to calcine and refine the gypsum.

Capacities

The future

Environmental protection

FGD gypsum is identical to natural gypsum, making it a valuable raw material. Find out more about FGD gypsum and resource conservation

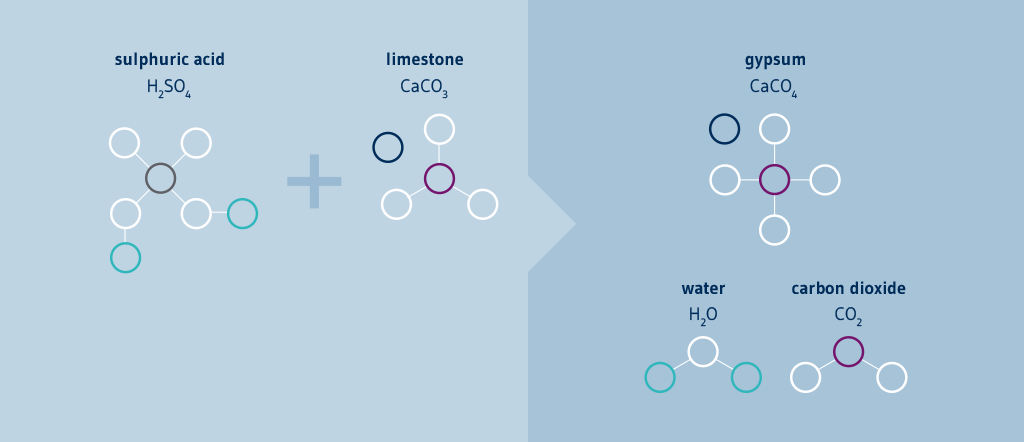

Do you remember the problem we had with acid rain back in the 80s? Across Germany, people were worried about their woods and forests being destroyed. The reason behind this was the pollutants in the emissions from power stations – such as sulphur which reacted with the oxygen and water in the air. This mixture created acidic rain which caused huge damage to both flora and fauna wherever it fell. To prevent this happening, power stations had to install so-called flue gas desulphurisation (FGD) systems to filter their waste gases. This may sound complicated but it is, in fact, a simple chemical process that binds sulphur dioxide with limestone and water. The by-product created as a result of this process is not waste but pure gypsum – known as FGD gypsum because of its origin.

Discover more about REMONDIS Production

No matter how practical FGD gypsum may be as an end product of flue gas desulphurisation systems, power stations still have to find someone to take it off their hands. This material, of course, is of no use to them whatsoever. This is most certainly not the case at REMONDIS. Or, more precisely, at REMONDIS Production. The company has its own gypsum business division, which is also located at the Lippe Plant. REMONDIS Production has both large storage facilities as well as the know-how and technology to transform the FGD gypsum from a raw material into a premium product for the building sector and other industries. This creates a win-win situation for all involved. Power stations have a reliable outlet for their FGD gypsum. REMONDIS has access to a valuable raw material – and is able to show, once again, that it can find a sustainable solution for practically every type of residual material.

The FGD gypsum is delivered to the Lippe Plant from a number of different hard coal, brown coal and industrial power stations located both in the immediate vicinity and further away – including the neighbouring Trianel coal-fired power station. All in all, REMONDIS Production processes 262,200 tonnes of FGD gypsum at the Lippe Plant every year. Able to hold up to 90,000 tonnes, the storage facilities are also an impressive size. The huge halls and their metre-high mountains of gypsum are always one of the highlights of the guided tours around the Lippe Plant. These enormous capacities have another great advantage other than being an amazing spectacle for the visitors: they ensure there is a permanent supply of gypsum for both the internal production facilities and external customers. No matter when or how much material may be needed.

The company in the REMONDIS Group that is responsible for all things gypsum is called CASEA

Yesterday: an aluminium plant; today: a recycling centre. Find out more about the conversion of the Lippe Plant

The FGD gypsum needs to be refined to make it just right for its various industrial uses. A unique process is deployed here to achieve this. Previous owners of the Lippe Plant had installed a circulating fluidised-bed kiln at the site to produce aluminium oxide and this is now being used as a drying and calcination facility for the FGD gypsum. One major advantage of this circulating fluidised-bed technology is that the whole process can be precisely controlled, enabling the properties of the output product to be strictly defined. The result is the premium quality anhydrite (the name given to gypsum which has had its water content removed) produced by REMONDIS Production.

Calcination

During the calcination process, the moist dihydrate (the FGD gypsum from the flue gas desulphurisation systems at coal-fired power stations) is dried and the water of crystallisation bound in the gypsum crystal fully evaporated. The resulting anhydrite is completely anhydrous, i.e. it contains absolutely no water. The material is stored in silos and used as the primary product for the next step of the process, the grinding stage.

Grinding

The anhydrite is transferred to a silo via pipes where a dosing screw conveyor feeds the material into the grinder. The surface of each individual anhydrite crystal is expanded during this grinding process. The anhydrite is then transported to other silos via various different conveyor units where it is stored until it is needed. The ground anhydrite can be used to make a number of products including ready-mix mortar. A variety of different additives are added to the anhydrite to make it suitable for other applications. This is carried out in a downstream mixing unit.

Mixing

A number of silos have been installed in the mixing tower for storing the ground anhydrite and the individual additives. Weigh feeders are used here to transfer the individual components – just like a recipe – to two weighing systems where they are weighed and then fed in batches into the mixing unit before being transported pneumatically (i.e. using compressed air) to various loading silos. The additives affect the way the anhydrite sets (setting time, fluidity, strength etc). The products from the mixer unit are used as flowing screed by the floor screed industry.

Shipping

For the most part, the material is shipped via silo trucks. Once the lorry has been driven under the relevant loading silo, the product is transferred from the silo to the truck via the loading equipment. Furthermore, these Lippe Plant products are also filled into different types of packaging (such as valve bags and big bags) and loaded onto articulated lorries.

Besides making anhydrite (i.e. dried gypsum), REMONDIS Production also uses a special process called hydrothermal dehydration at the Lippe Plant to produce alpha hemihydrates. These are used as a base material for producing construction chemicals as well as to make moulding and dental plaster.

Gypsum-based products are part of everyone’s lives – yours, too. Of course, we all know of the plaster casts used at hospitals. Gypsum, though, often plays an important role in products that we wouldn’t immediately recognise or indeed that we wouldn’t expect at all. One reason for this is because many industries use a processed form of gypsum. Primarily as a binding agent or additive. REMONDIS Production produces both on a grand scale – in total, 262,200 tonnes.

Just one example of the synergies at the Lippe Plant: wall plaster containing the white mineral CASUL

Unlike natural gypsum, FGD gypsum is always of the same high quality

FGD gypsum has a number of decisive advantages compared to natural gypsum which is mined in quarries. It is true that natural material – limestone – is needed to produce FGD gypsum, i.e. in the flue gas desulphurisation systems. All in all, though, this process helps preserve both natural resources and landscapes. What’s more, less energy is used compared to the amount needed to process natural gypsum. And less energy means fewer carbon emissions. Talking of emissions: REMONDIS’ Lippe Plant also has a number of arguments in its favour when it comes to FGD gypsum and transport – thanks to its proximity to the Ruhr region which is home to a considerable number of power stations.

When you think of which resources are becoming scarce, then it is our planet’s natural raw materials that automatically come to mind. It might, therefore, come as a surprise to read here that it may soon be difficult to get hold of the waste raw material, FGD gypsum. And this is a situation which cannot be avoided. Why? Because Germany’s gradual switch from fossil fuels to renewables will lead to more and more coal-fired power stations being shut down and, as a result, less and less FGD gypsum being produced. Sooner or later, the various industries will be forced to increase their consumption of natural gypsum. This is, of course, not a reason to cast doubt on the meaningfulness or the need to switch to renewables. It is, however, an excellent example of just how complex industrial interrelationships are and how everything is connected to each other in today’s world.

The number of coal-fired power stations will fall – as will volumes of FGD gypsum – as Germany switches over to renewable energy

The number of people moving to large cities continues unabated. With the world’s population soon to reach the ten-billion mark, our towns are going to get very crowded indeed. If this ongoing urbanisation is to be managed, then homes must be built on as little space as possible. Gypsum will be able to play an important role here. Autoclaved aerated concrete made from gypsum, for example, is much lighter than stone – reducing the weight of a building and making it easier to build upwards. Moreover, gypsum-based building materials have a particularly low volume which means less space is generally needed for building. Gypsum also wins the argument when it comes to time. More and more floor screed containing gypsum-based binding agents is being used today as this material dries particularly quickly – which means, of course, that construction projects can be completed faster.

When it comes to producing binding agents, REMONDIS Production’s operations go hand in hand with those of CASEA. This company also belongs to the REMONDIS Group and unites all of the Group’s gypsum services. Find out more at casea.de

Diese Seite verwendet aktuelle Techniken, die in dem von Ihnen verwendeten Browser unter Umständen nicht korrekt

angezeigt werden können.

Bitte aktualisieren Sie Ihren Internet-Explorer oder weichen auf einen anderen Browser wie Chrome oder

Firefox aus.

Schließen