The world of the

REMONDIS Lippe Plant

Dirt and contaminants aren’t always as obvious as they are here on this picture. Healthcare waste, in particular, can contain invisible but highly infectious germs and it is essential that these substances are made safe. The unique REKOMED sterilisation process is so successful at doing this that the material can be used as a refuse-derived fuel (RDF).

Guaranteed safe disposal

No chance for viruses or bacteria – thanks to a fully automated sterilisation system.

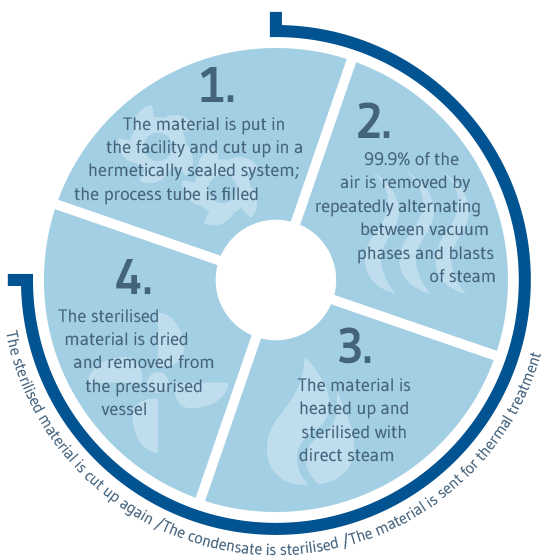

The principle of vacuum sterilisation

A description of the facility

Special treatment requirements apply to infectious waste - for example from hospitals. These materials have to be rendered harmless and incinerated at very high temperatures in hazardous waste incineration plants. However, this disposal process does not always provide the best possible solution for the waste in terms of energy efficiency. REMONDIS Medison – a healthcare waste specialist – has developed an innovative and efficient solution to this problem. They have come up with a treatment method that transforms infectious waste into a sterile and, as a result, harmless state so that it can be sent for thermal treatment. The name of this treatment system is REKOMED and it is being operated by REMONDIS Medison at the Lippe Plant.

Every year, REMONDIS Medison uses its REKOMED system to process up to 5,400 tonnes of hospital waste – generating enough energy to cover the annual needs of 4,000 households

Even if the final goal is energy recovery, the priority of this particular treatment process is to sterilise infectious waste. This facility is there to turn hazardous substances into harmless materials. And, by doing so, it is playing a key role in keeping people safe and healthy. Germs, viruses and spores are killed off completely by this sterilisation process. Importantly, everything is fully automated so that the staff do not come into contact with the material at any stage of the procedure. This is all made possible because the whole system is fully enclosed – from the moment the material is placed into the facility through to the final sterilisation stage. What’s more, no one is put at risk either if the facility has to be repaired or serviced as all the individual pieces of machinery at the plant have a self-sterilising function. Experts regularly use microbiological and physical tests to check that the plant is operating correctly and effectively.

The secure bins and their contents are placed inside the facility where they are first cut up

The technology used during the REKOMED sterilisation process is a mixture of vacuum and steam treatment. This combination of processes guarantees that the material being treated is always successfully sterilised. Any residual steam and condensate generated by this treatment process are also systematically made safe.

Find out more about REMONDIS Medison – the developer and operator of the REKOMED treatment facility – at remondis-medison.de

Diese Seite verwendet aktuelle Techniken, die in dem von Ihnen verwendeten Browser unter Umständen nicht korrekt

angezeigt werden können.

Bitte aktualisieren Sie Ihren Internet-Explorer oder weichen auf einen anderen Browser wie Chrome oder

Firefox aus.

Schließen