The world of the

REMONDIS Lippe Plant

Far too many recyclable materials are being lost despite the fact that Germany has a series of different bins for households and made it obligatory for businesses to separate their waste. Just one example: large amounts of materials are ending up in the black bin that simply don’t belong there. Even though black bins should only be used for collecting non-recyclable materials, they often contain a whole range of other items – from old paper and plastic packaging, to aluminium cans and drinks bottles, all the way through to old electronic devices. All of these products should be easy to recycle. The emphasis here being on the word ‘should’. There’s normally no way back for them once they’ve been accidentally thrown away into the residual waste bin. They end up being incinerated with the other non-recyclable contents in the black bin. One solution to this problem could be to send residual and mixed waste to sorting plants rather than taking it straight to waste-to-energy plants for incineration. This is precisely what REMONDIS is doing at the state-of-the-art GWA RE facility – a collaboration

This is precisely what REMONDIS is doing at the state-of-the-art GWA RE facility – a collaboration with GWA Kreis Unna – at the Lippe Plant.

Plant capacity: 180,000 tonnes of municipal and commercial waste a year

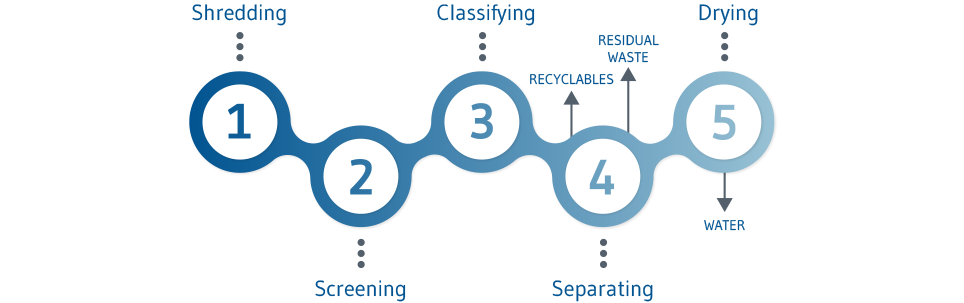

All the different types of essential sorting technology and more can be found at the GWA RE recyclables treatment plant. It uses conventional mechanical processes such as shredders and screening equipment as well as a range of sorting machines including air separators, magnetic separators and infrared technology. All in all, an impressive combination of sorting and classification systems has been installed at this facility that is second to none. The mixed waste delivered to the plant is systematically sorted and separated into recyclable and residual materials. The recyclables – which include paper, wood, plastics, metals and even water (recovered from drying organic materials) – can then be sent on for further processing so that they can be reused.

Materials that can’t be recovered for reuse are used as climate-friendly refuse-derived fuel (RDF) by power stations and cement works as a substitute for fossil fuels such as coal, oil and gas. Some of the RDF from the GWA plant is sent straight to the fluidised-bed power station at the Lippe Plant.

GWA RE – a film about the plant

The system used to treat mixed waste at the GWA RE plant is an excellent example of a future-oriented recycling strategy. At the end of the day, it’s simply not enough to make do with the recyclable materials recovered by the various collection schemes. This neither meets the statutory obligation to observe the waste hierarchy nor does it live up to society’s responsibility to conserve as many natural resources as possible. Which means that the goal must be to set up facilities like the one at REMONDIS’ Lippe Plant across the whole of Germany so that the very most can be made of the huge recycling potential hidden in mixed waste.

Fewer and fewer politicians and indeed society as a whole are prepared to accept the way waste is currently being handled – not least because of the urgent need to cut emissions. Which is why waste-to-energy plants will have to start paying a carbon tax from the beginning of 2024. It will, therefore, become a financial burden to incinerate more waste than is strictly necessary. If thermal treatment is to continue to be profitable in Germany in the future, then there will be no choice but to sort residual waste. Otherwise, local residents may end up having to pay even higher waste management charges. Not to mention the fact that the higher costs for thermal treatment may result in waste taking a different and unwelcome path. For example to landfills in other countries.

Diese Seite verwendet aktuelle Techniken, die in dem von Ihnen verwendeten Browser unter Umständen nicht korrekt

angezeigt werden können.

Bitte aktualisieren Sie Ihren Internet-Explorer oder weichen auf einen anderen Browser wie Chrome oder

Firefox aus.

Schließen