The world of the

REMONDIS Lippe Plant

Despite being specialists in our field, our industry still comes up with some surprises – simply because we don’t know what new recycling challenges may be waiting for us in the future. What we do know is that the best way to prepare ourselves for what is coming is to create synergies that combine many different areas of expertise and technology. Thanks to these collaborations, we are able to return 1.6 million tonnes of residual materials to production cycles. We’re ready for whatever the future may have in store.

Inspiring each other

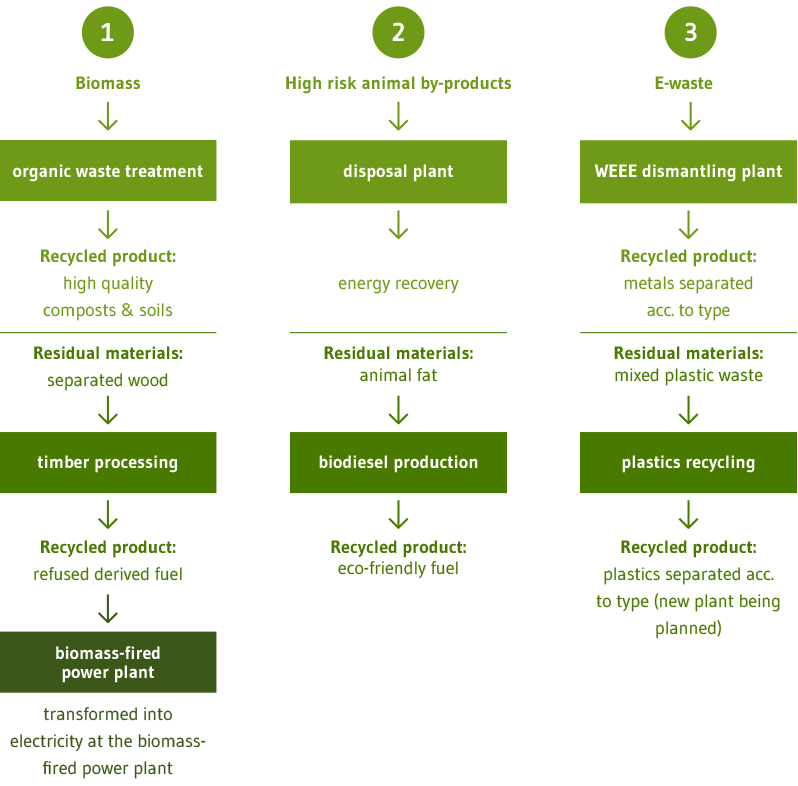

Residual waste here, a raw material there: whatever is left over at one facility can be put to good use at another.

Who works with who?

Synergies mean greater efficiency and better quality

The Lippe Plant is not only Europe’s largest industrial recycling centre, it also a perfect example of efficiency and teamwork. All the companies located there can, for example, use the site’s infrastructure including the roads and paths, the plant security & fire station and the supply networks. Electricity, steam and compressed air can be accessed quickly thanks to the plant’s own fluidised-bed power station as can professional wastewater treatment which is provided by the experts at REMONDIS Production. What’s more, the Lippe Plant is able to organise and carry out comprehensive analyses of all input material itself – thanks to the laboratory services delivered by Umwelt Control Labor.

Over 800 trucks travel to the Lippe Plant every day. As the incoming material can often be used for more than one application (referred to as “cascaded use”), it may be processed by several different facilities

One of the biggest advantages of the Lippe Plant is the way the different fields of business work together to increase the number of material life cycles that can be closed. The idea behind this is simple: a substance that is left over after one recycling process can be used or further treated by another. Sometimes, different processes and fields of business create joint structures and develop new activities together. Just one example here is the sodium aluminate ALUMIN that is produced from waste containing aluminium and is used to make the premium quality white mineral CASUL.

A few examples of the synergies at the Lippe Plant – step by step just for you

230 hectares of perfect collaboration work: REMONDIS’ Lippe Plant in Lünen

The following provides an overview of all the synergies at the Lippe Plant. Select a field of business to find out how it is linked to the others.

Diese Seite verwendet aktuelle Techniken, die in dem von Ihnen verwendeten Browser unter Umständen nicht korrekt

angezeigt werden können.

Bitte aktualisieren Sie Ihren Internet-Explorer oder weichen auf einen anderen Browser wie Chrome oder

Firefox aus.

Schließen